Simulation 3D Fisheye Camera

Fisheye camera sensor model in 3D simulation environment

Libraries:

UAV Toolbox /

Simulation 3D

Automated Driving Toolbox /

Simulation 3D

Simulink 3D Animation /

Simulation 3D /

Sensors

Description

Note

Simulating models with the Simulation 3D Fisheye Camera block requires Simulink® 3D Animation™ and Computer Vision Toolbox™.

The Simulation 3D Fisheye Camera block provides an interface to a camera with a fisheye lens in a 3D simulation environment. This environment is rendered using the Unreal Engine® from Epic Games®. The sensor is based on the fisheye camera model proposed by Scaramuzza [1]. This model supports a field of view of up to 195 degrees. The block outputs an image with the specified camera distortion and size. You can also output the location and orientation of the camera in the world coordinate system of the scene.

If you set Sample time to -1, the block uses the

sample time specified in the Simulation 3D Scene Configuration block. To use

this sensor, you must include a Simulation 3D Scene Configuration block in your

model.

Tip

The Simulation 3D Scene Configuration block must execute before the Simulation 3D Fisheye Camera block. That way, the Unreal Engine 3D visualization environment prepares the data before the Simulation 3D Fisheye Camera block receives it. To check the block execution order, right-click the blocks and select Properties. On the General tab, confirm these Priority settings:

Simulation 3D Scene Configuration —

0Simulation 3D Fisheye Camera —

1

For more information about execution order, see How Unreal Engine Simulation for Automated Driving Works.

Examples

Ports

Input

Output

Parameters

Tips

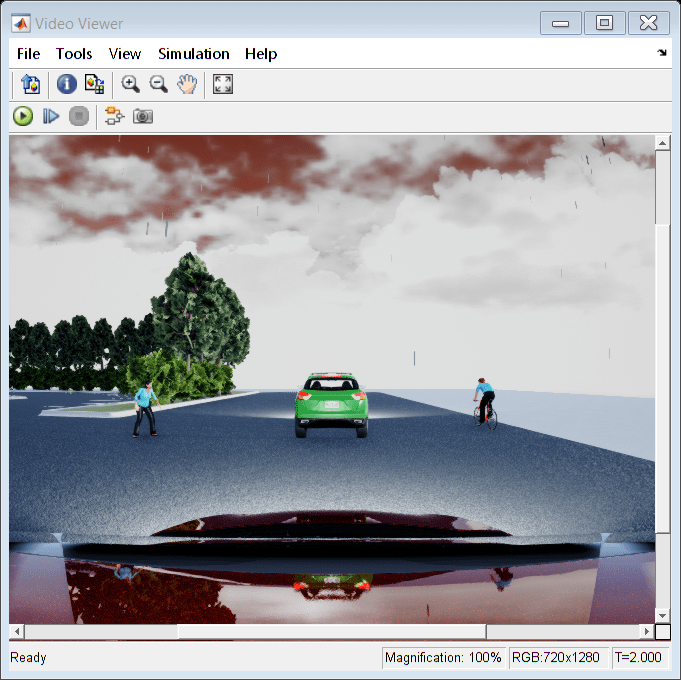

To visualize the camera images that are output by the Image port, use a Video Viewer or To Video Display block.

Because the Unreal Engine can take a long time to start up between simulations, consider logging the signals that the sensors output. You can then use this data to develop perception algorithms in MATLAB®. See Mark Signals for Logging (Simulink).

You can also save image data as a video by using a To Multimedia File block. For an example of this setup, see Design Lane Marker Detector Using Unreal Engine Simulation Environment.

Algorithms

References

[1] Scaramuzza, D., A. Martinelli, and R. Siegwart. "A Toolbox for Easy Calibrating Omindirectional Cameras." Proceedings to IEEE International Conference on Intelligent Robots and Systems (IROS 2006). Beijing, China, October 7–15, 2006.