Lead Screw Joint

Joint with coupled rotational and translational degrees of freedom

Libraries:

Simscape /

Multibody /

Joints

Description

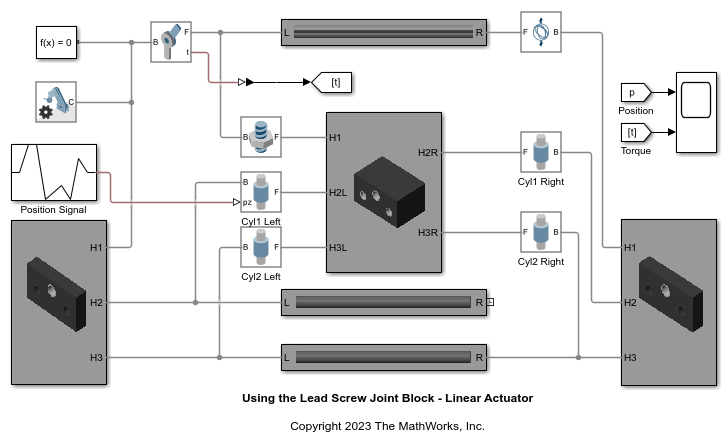

The Lead Screw Joint block represents a joint that has one degree of freedom and models a pair of coupled rotation and translation, as shown in the image.

During simulation, the joint constrains the z-axes of the base and follower frames to be aligned. The follower frame origin can translate along the base z-axis while the follower x-axis and y-axis rotate about the base frame z-axis. The translation is proportional to the rotation based on the value of the Lead and Direction parameters.

To specify the target of the initial state for the joint, use the parameters under State Targets. You can specify the targets based on the relative rotation or translation between the joint frames. To specify the joint mode configuration, use the Mode parameter. For more details, see Mode Configuration under the Ports and Parameters sections.

The joint block has ports that output sensing data, such as position, velocity, acceleration, force, and torque, that you can use to perform analytical tasks on a model.

Faults

Using mode faults, you can change the joint modes during a simulation without modifying the

model design. The fault injection overrides the mode setting. For example, if a joint has

the Mode parameter set to Locked and the

Fault behavior parameter set to Disengaged, the

joint becomes disengaged.

To add a mode fault to a joint block, click on the joint block, in the Simscape Block tab, and the Faults section,

click Fault > Add Fault.

Alternatively, you can click the joint block, hover over the ellipsis to open the action

bar, and click the Add a fault on the block icon ![]() . You can add multiple faults to a joint block, but the

joint block can have only one active fault during a simulation.

. You can add multiple faults to a joint block, but the

joint block can have only one active fault during a simulation.

As you add faults, in the Property Inspector, under the Fault

section, specify the behavior and the trigger type of the fault. To define the fault

behavior, click the link next to the Fault Behavior. This

joint supports Locked, Normal, or

Disengaged mode. The joint blocks support these trigger types:

Always on, Timed, Manual, and

Conditional. For more details of these trigger types, see Set Fault Triggers. To trigger a

conditional fault, you can use Simulink signals, Simscape language blocks, and MATLAB

workspace variables. To set the active fault for a block, use the Fault Table. For more

details, see Access the Fault Table and Fault Dashboard.

To enable fault simulation, in the Simscape Block tab and

the Faults section, turn on the Fault

Simulation button. The fault simulation is on when the button is green and

the status is on. The simulation logs the trigger status

data. To view the data, use the Simulation Data

Inspector. Also, you can see the fault status and a summary of the triggered

faults in the Fault Dashboard. To open the Fault Dashboard, in the Simscape Block tab, click Faults >

Fault Dashboard.

To create and modify faults, you can also use Simscape™ and Simulink® fault functions. For more details, see the function section of the Simulink Fault Controls and Simscape Faults Interface.