Texas Instruments

Motor Control Blockset™ には、Texas Instruments ハードウェアに展開できる例が用意されています。

注目の例

開ループ制御での三相 AC モーターの駆動と ADC オフセットのキャリブレーション

この例では、開ループ制御 (スカラー制御またはボルト/ヘルツ制御とも呼ばれる) を使用してモーターを駆動します。この手法では、モーターからのいずれのフィードバックも使用せずに、固定子電圧と周波数を変えて回転子速度を制御します。この手法を使用してハードウェア接続の整合性を確認できます。開ループ制御の一定速度のアプリケーションでは、固定周波数のモーター電源を使用します。開ループ制御の可変速度のアプリケーションでは、回転子速度を制御するために可変周波数の電源が必要です。固定子の磁束を一定に保つために、電源電圧の振幅がその周波数と比例するように維持します。

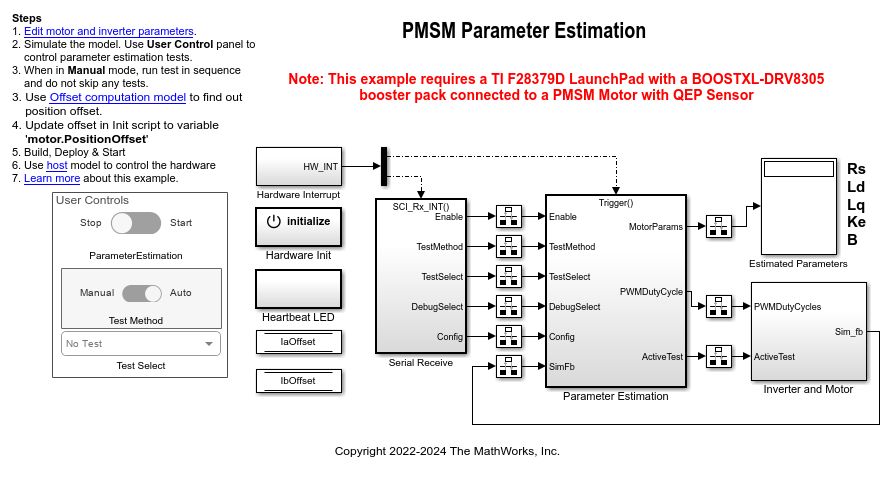

Estimate PMSM Parameters Using Parameter Estimation Blocks

Uses the parameter estimation blocks provided by Motor Control Blockset™ to estimate these parameters of a permanent magnet synchronous motor (PMSM) with a quadrature encoder sensor:

PMSM のセンサーレス ベクトル制御

この例では、三相永久磁石同期モーター (PMSM) の角速度を制御するためのベクトル制御 (FOC) 手法を実装します。FOC の詳細については、ベクトル制御 (FOC)を参照してください。

Hall Offset Calibration for PMSM

Calculates the offset between the rotor direct axis (d-axis) and position detected by the Hall sensor. The field-oriented control (FOC) algorithm needs this position offset to run the permanent magnet synchronous motor (PMSM) correctly. To compute the offset, the target model runs the motor in the open-loop condition. The model uses a constant (voltage along the stator's

d-axis) and a zero (voltage along the stator's

q-axis) to run the motor (at a low constant speed) by using a position or ramp generator. When the position or ramp value reaches zero, the corresponding rotor position is the offset value for the Hall sensors.

ホール センサーを使用した PMSM のベクトル制御

この例では、三相永久磁石同期モーター (PMSM) の角速度を制御するためのベクトル制御 (FOC) 手法を実装します。この FOC アルゴリズムには回転子の位置フィードバックが必要であり、それをホール センサーで取得します。FOC の詳細については、ベクトル制御 (FOC)を参照してください。

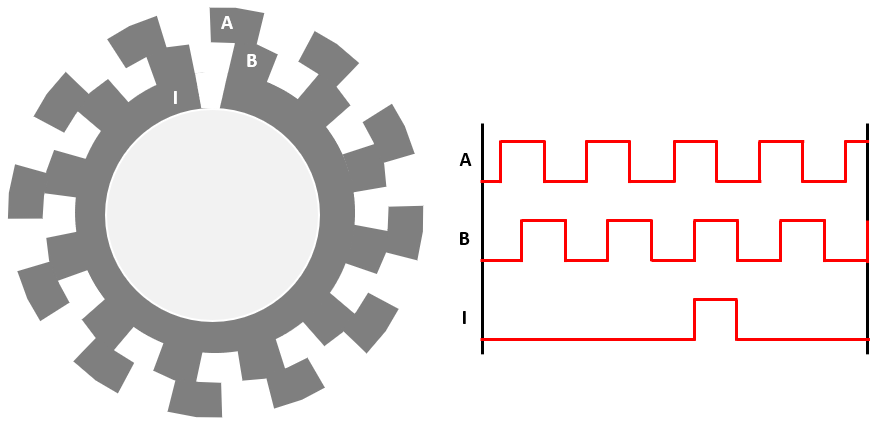

Quadrature Encoder Offset Calibration for PMSM

Calculates the offset between the d-axis of the rotor and encoder index pulse position as detected by the quadrature encoder sensor. The control algorithm (available in the field-oriented control and parameter estimation examples) uses this offset value to compute an accurate and precise position of the d-axis of rotor. The controller needs this position to implement the field-oriented control (FOC) correctly in the rotor flux reference frame (d-q reference frame), and therefore, run the permanent magnet synchronous motor (PMSM) correctly.

直交エンコーダーを使用した PMSM のベクトル制御

この例では、三相永久磁石同期モーター (PMSM) の角速度を制御するためのベクトル制御 (FOC) 手法を実装します。この FOC アルゴリズムには回転子の位置フィードバックが必要であり、それを直交エンコーダー センサーで取得します。FOC の詳細については、ベクトル制御 (FOC)を参照してください。

PMSM の弱め界磁制御 (MTPA を使用)

この例では、三相永久磁石同期モーター (PMSM) のトルクと角速度を制御するためのベクトル制御 (FOC) 手法を実装します。この FOC アルゴリズムには回転子の位置フィードバックが必要であり、それを直交エンコーダー センサーで取得します。FOC の詳細については、ベクトル制御 (FOC)を参照してください。

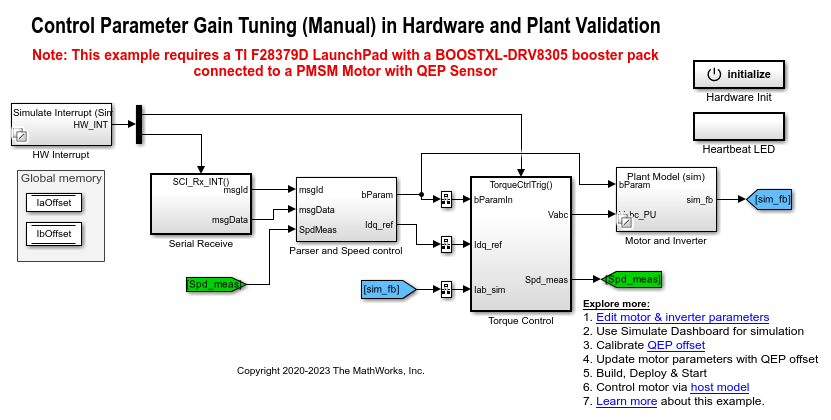

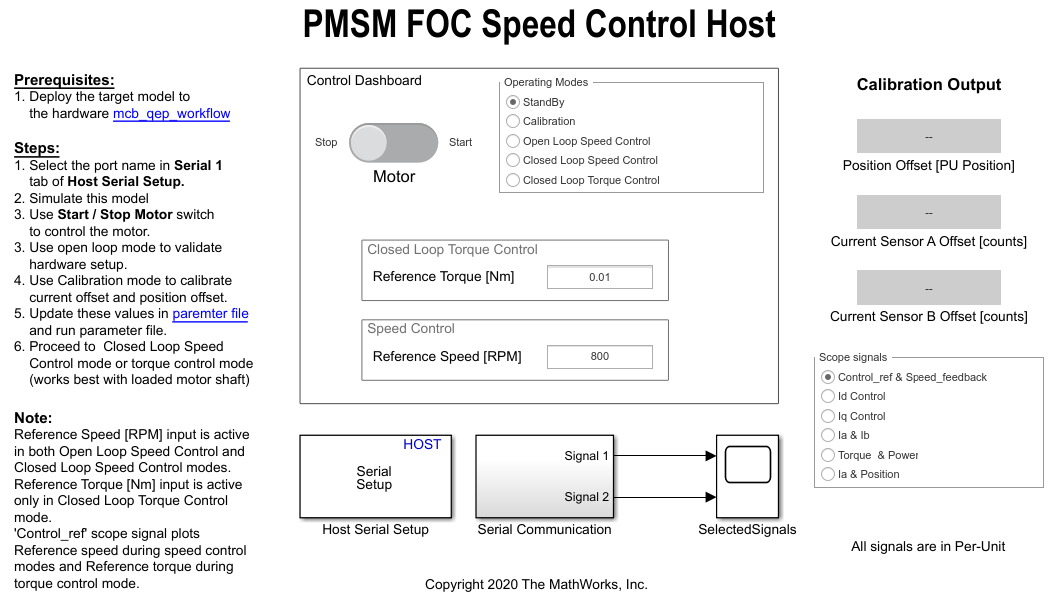

Tune Control Parameter Gains in Hardware and Validate Plant

Uses field-oriented control (FOC) to run a three-phase permanent magnet synchronous motor (PMSM) in different modes of operation for plant validation. FOC algorithm implementation needs the real-time feedback of the rotor position. This example uses a quadrature encoder sensor to measure the rotor position. For details about FOC, see ベクトル制御 (FOC).

SI 単位を使用した PMSM のベクトル制御

この例では、三相永久磁石同期モーター (PMSM) の角速度を制御するためのベクトル制御 (FOC) 手法を実装します。ただし、この例の FOC アルゴリズムでは、pu 表現の数量の代わりに (pu 単位系の詳細についてはPer-Unit Systemを参照)、SI 単位の信号を使用して計算を実行します。それらの信号とその SI 単位は次のとおりです。

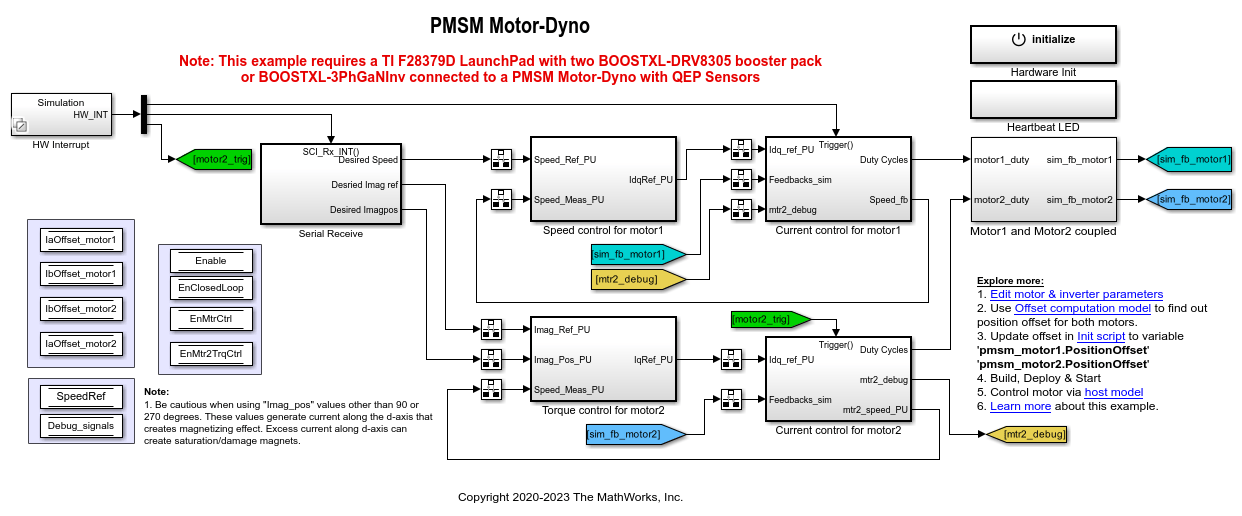

Control PMSM Loaded with Dual Motor (Dyno)

Uses field-oriented control (FOC) to control two three-phase permanent magnet synchronous motors (PMSM) coupled in a dyno setup. Motor 1 runs in the closed-loop speed control mode. Motor 2 runs in the torque control mode and loads Motor 1 because they are mechanically coupled. You can use this example to test a motor in different load conditions.

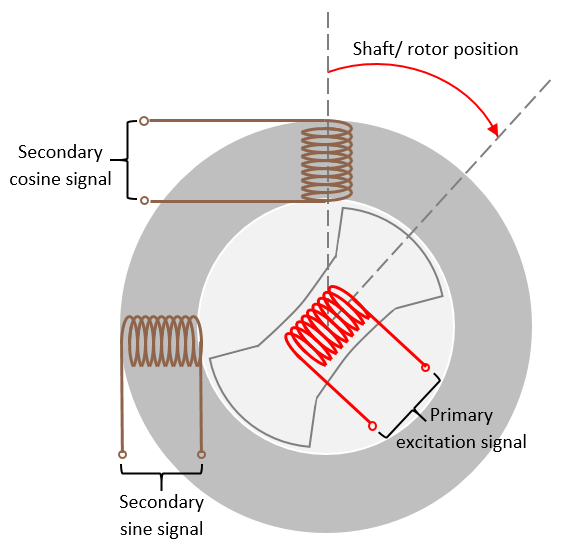

Monitor Resolver Using Serial Communication

Use the resolver sensor to measure the rotor position. The resolver consists of two stator (secondary) windings placed orthogonally around the resolver rotor (primary) winding. After you mount the resolver sensor over a PMSM, the resolver rotor winding rotates with the shaft of the running motor. Meanwhile, the controller provides a fixed-frequency excitation signal (alternating sinusoidal or square pulse) to the primary winding.

Simscape Electrical を使用したインバーターのスイッチング ダイナミクスのモデル化

この例では、ベクトル制御 (FOC) を使用して三相永久磁石同期モーター (PMSM) の角速度を制御します。Motor Control Blockset™ の Average Value Inverter ブロックの代わりに次の Simscape™ Electrical™ ブロックを使用するオプションが用意されています。

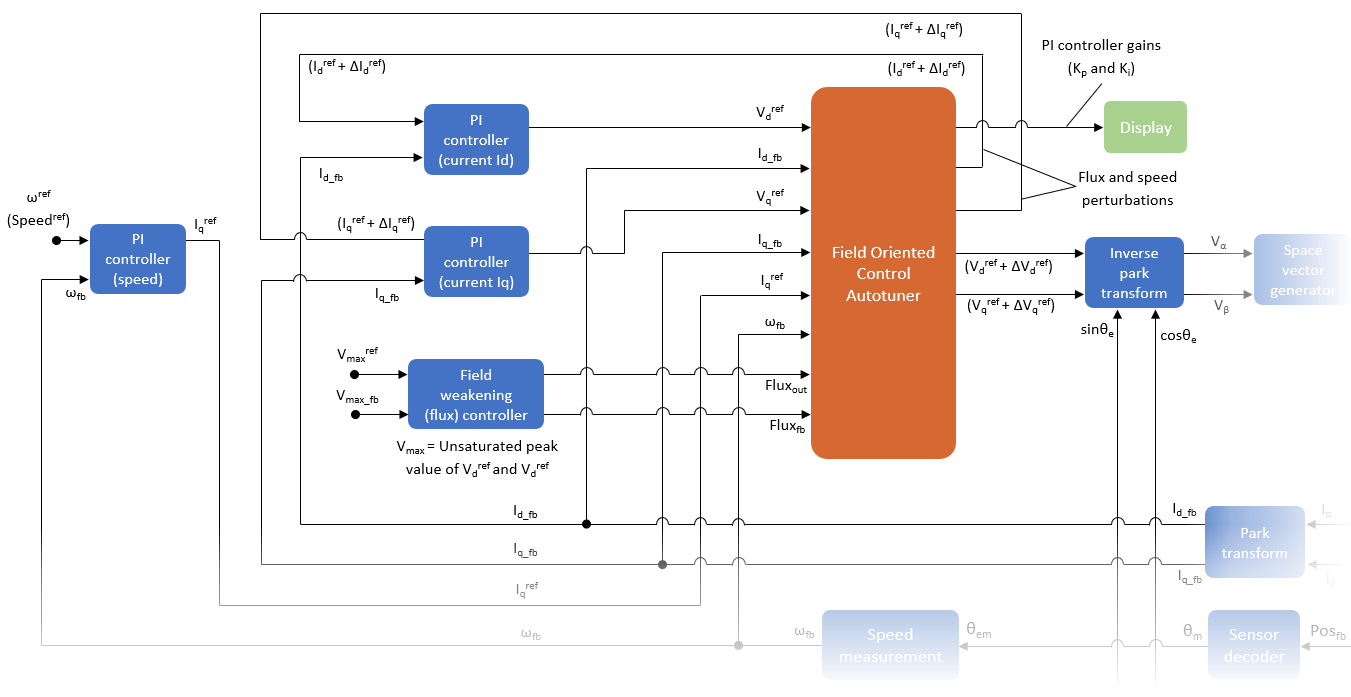

Tune PI Controllers Using Field Oriented Control Autotuner

Computes the gain values of PI controllers available in the speed and current control loops by using the Field Oriented Control Autotuner block. For details about this block, see Field Oriented Control Autotuner. For details about field-oriented control, see ベクトル制御 (FOC).

Tune PI Controllers (in Field-Weakening Control Mode) Using FOC Autotuner Block

Uses the Field Oriented Control Autotuner block to compute the gain values of the PI controllers available in the speed, current, and flux control loops of a field-weakening control algorithm. For details about this block, see Field Oriented Control Autotuner.

Position Control of PMSM Using Quadrature Encoder

Implements the field-oriented control (FOC) technique to control the position of a three-phase permanent magnet synchronous motor (PMSM). The FOC algorithm requires rotor position feedback, which it obtains from a quadrature encoder sensor.

MATLAB Project for FOC of PMSM with Quadrature Encoder

This MATLAB® project provides a motor control example model that uses field-oriented control (FOC) to run a three-phase permanent magnet synchronous motor (PMSM) in different modes of operation. Implementing the FOC algorithm needs real-time rotor position feedback. This example uses a quadrature encoder sensor to measure the rotor position. For details about FOC, see ベクトル制御 (FOC).

Frequency Response Estimation of PMSM Using Field-Oriented Control

Performs frequency response estimation (FRE) of a plant model running a three-phase permanent magnet synchronous motor (PMSM). When you simulate or run the model on the target hardware, the model runs tests to estimate the frequency response as seen by each PI controller (also known as raw FRE data) and plots the FRE data to provide a graphical representation of the plant model dynamics.

Integrate MCU Scheduling and Peripherals in Motor Control Application

Identify and resolve issues with respect to peripheral settings and task scheduling early during development.

Partition Motor Control for Multiprocessor MCUs

Partition real-time motor control application on to multiple processors to achieve design modularity and improved control performance.

Estimate Initial Rotor Position Using Pulsating High-Frequency and Dual-Pulse Methods

Estimates the initial position (in electrical radians) of a stationary interior PMSM by using pulsating high-frequency (PHF) injection and dual pulse (DP) techniques.

Field-Oriented Control (FOC) of PMSM Using Hardware-in-the-Loop (HIL) Simulation

Uses hardware-in-the-loop (HIL) simulation to implement the field-oriented control (FOC) algorithm to control the speed of a three-phase permanent magnet synchronous motor (PMSM). The FOC algorithm requires rotor position feedback, which is obtained by a quadrature encoder sensor. For more information on FOC, see ベクトル制御 (FOC).

Direct Torque Control of PMSM Using Quadrature Encoder or Sensorless Flux Observer

Implements direct torque control (DTC) technique to control the speed of a three-phase permanent magnet synchronous motor (PMSM). Direct Torque Control (DTC) is a vector motor control technique that implements motor speed control by directly controlling the flux and torque of the motor. The example algorithm needs motor currents and position feedback from PMSM. It uses space vector pulse-width modulation (DTC-SVPWM) variant of DTC, which uses space vector modulation (SVM) to produce the pulse-width modulation (PWM) duty cycles that are used by the inverter. For more details about the DTC-SVPWM algorithm used in this example, see 直接トルク制御 (DTC).

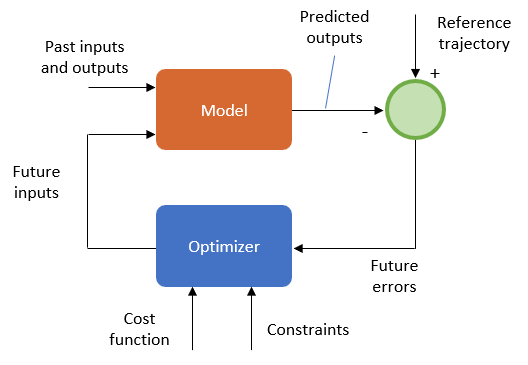

Run Field Oriented Control of PMSM Using Model Predictive Control

Uses Model Predictive Control (MPC) to control the speed of a three-phase permanent magnet synchronous motor (PMSM). MPC is a control technique that tunes and optimizes the inputs to a control system to minimize the error in the predicted system output and achieve the reference control objective over a period of time. This technique involves solving the objective function and finding an optimal input sequence at every sample time (). After each time step, the current state of the plant is considered as the initial state and the above process is repeated.

PIL テストを使用したコードの検証とプロファイリング

この例では、Texas Instruments® LAUNCHXL-F28379D ハードウェア ボードでの PIL プロファイリングについて説明します。プロセッサインザループ (PIL) シミュレーションでは、制御アルゴリズムはターゲット ハードウェアで実行されますが、プラント モデルはホスト マシンで実行されます。プラント モデルは、コントローラーに対する入力信号と出力信号をシミュレートし、シリアル通信インターフェイスを使用してコントローラーと通信します。この機能により、PIL シミュレーションを使用してターゲット ハードウェアでの実行時間を特定し、ホスト マシンでモデルをシミュレートする実行時間と比較できます。

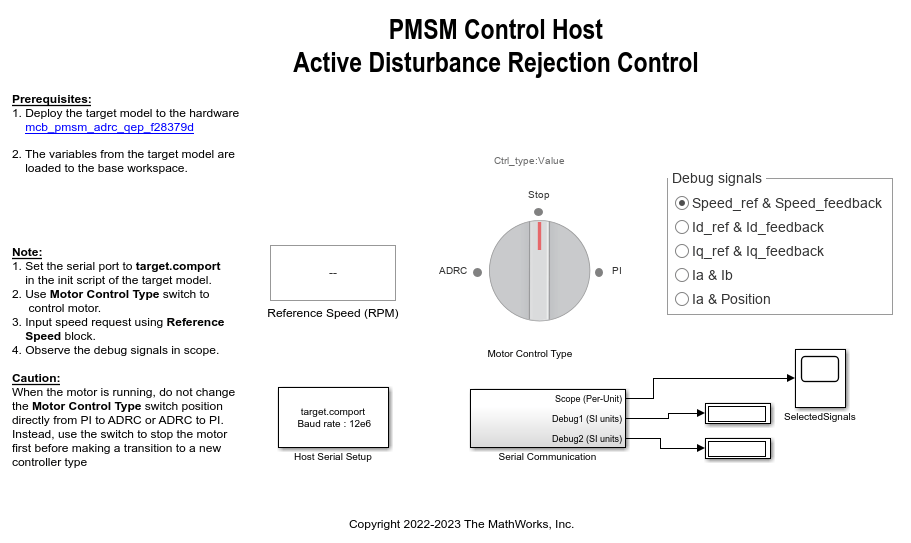

Implement PMSM Speed Control Using Active Disturbance Rejection Control

Implement active disturbance rejection control (ADRC) of the speed of a permanent magnet synchronous motor (PMSM) modeled in Simulink® using the Active Disturbance Rejection Control (Simulink Control Design) block. You can use the example to implement field-oriented control (FOC) using either a proportional integral (PI) or ADRC-based controller to run the motor in the speed control mode. Therefore, you can compare the performance of the PI and ADRC controllers.

Swap Motors with Single Model Deployment of Sensor-Based FOC Algorithm

Run a permanent magnet synchronous motor (PMSM) in an industrial drive application setup using position-sensor-based field-oriented control (FOC). Industrial drives enable you to swap motors in real-time without repeated deployment of code. An industrial drive setup needs a fixed inverter and software that has the ability to adapt the control algorithm according to the new motor using only the updated nameplate parameters.

Swap Motors with Single Deployment of Sensorless FOC Algorithm

Run a permanent magnet synchronous motor (PMSM) in an industrial drive application setup using a sensorless field-oriented control (FOC) algorithm. The example uses a sensorless Flux Observer to estimate the motor position. Industrial drives enable you to replace a motor with a new one without repeated deployment of code. An industrial drive setup needs only nameplate parameters to adapt the software to the new motor.

Generate Motor Control Models for Selected Algorithm and Hardware

Use Motor Control Blockset™ to generate a Simulink® model that is configured for a specific hardware and motor control technique.

BLDC モーターのホール センサー シーケンス キャリブレーション

この例では、開ループ制御における回転子の位置ゼロに関するホール センサー シーケンスを計算します。このワークフローは、ホール センサーにラベルを付けたり、スイッチング シーケンスを派生したりすることなく、6 段階整流を使用してモーターを回転できるようにします。この例を実行してホール シーケンスを取得し、そのホール シーケンスを Six Step Commutation ブロックで使用して、センサー フィードバックを使用した BLDC モーターの 6 段階整流の例で説明されているように閉ループでモーターを駆動します。

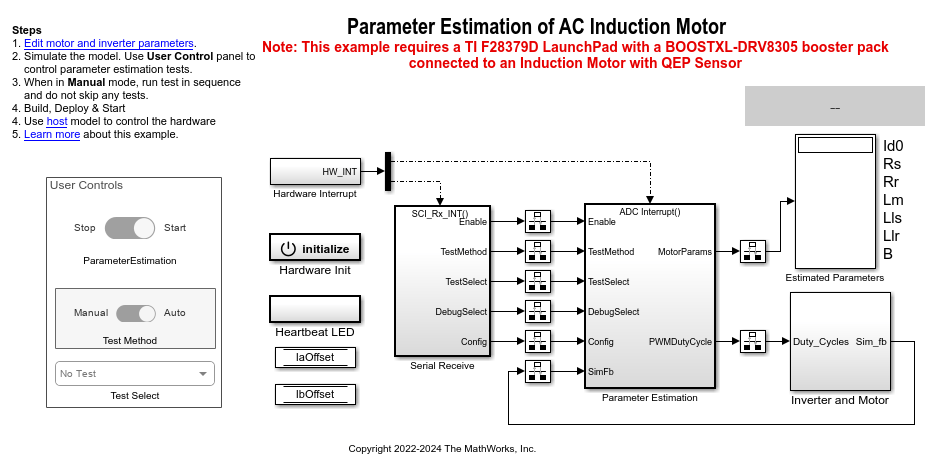

Estimate Induction Motor Parameters Using Parameter Estimation Blocks

Uses the parameter estimation blocks provided by Motor Control Blockset™ to estimate these parameters of an AC induction motor (ACIM):

速度センサーを使用した誘導モーターのベクトル制御

この例では、三相交流誘導モーター (ACIM) の角速度を制御するためのベクトル制御 (FOC) 手法を実装します。この FOC アルゴリズムには回転子の速度フィードバックが必要であり、この例ではそれを直交エンコーダー センサーを使用して取得します。FOC の詳細については、ベクトル制御 (FOC)を参照してください。

誘導モーターのセンサーレス ベクトル制御

この例では、センサーレス位置推定を使用して、三相交流誘導モーター (ACIM) の角速度を制御するためのベクトル制御 (FOC) 手法を実装します。FOC の詳細については、ベクトル制御 (FOC)を参照してください。

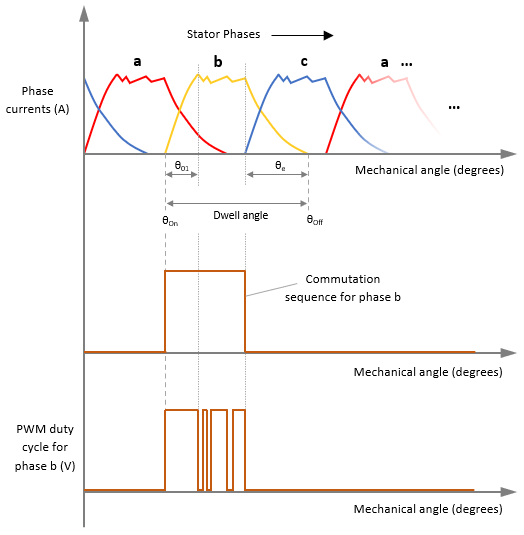

Commutation of SRM Using Sensor Feedback

Implements a commutation system to control the speed of a three-phase 12/8 switched reluctance motor (SRM).

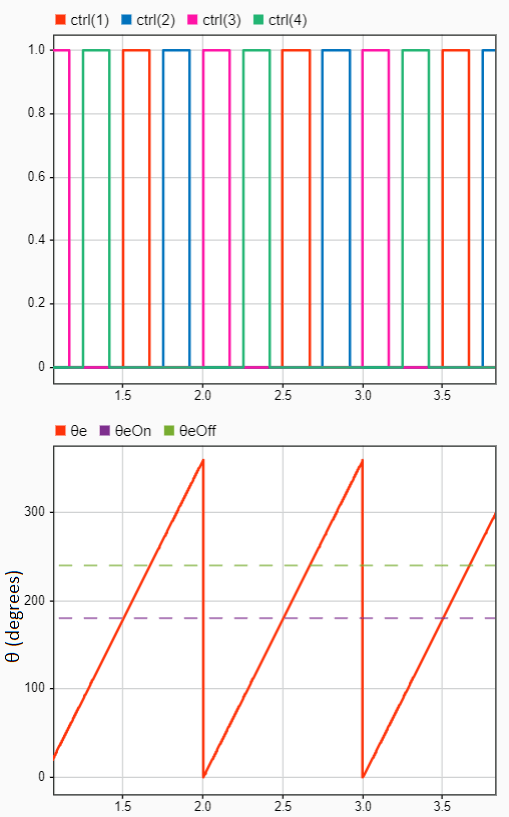

Dwell Angle Computation for SRM Speed Control

Compute the dwell angle of a 12/8 switched reluctance motor (SRM) online (while the motor runs). The example then uses the computed dwell angle along with a delta controller to control the motor speed.

Sensorless Field-Oriented Control of PMSM Using DC Shunt Current Sensing

Implement sensorless field-oriented control (FOC) using only a single DC bus-based current measurement to run a permanent magnet synchronous motor (PMSM).

Sensorless Field-Oriented Control of PMSM Using I-F Control-Based Startup

Implements field-oriented control (FOC) using sensorless position estimation and I-F control-based startup to control the speed of a three-phase permanent magnet synchronous motor (PMSM).

Field-Oriented Control of PMSM Using Position Estimated by Neural Network

Implement field-oriented control (FOC) of a permanent magnet synchronous motor (PMSM) using a rotor position estimated by an autoregressive neural network (ARNN) trained with Deep Learning Toolbox™.

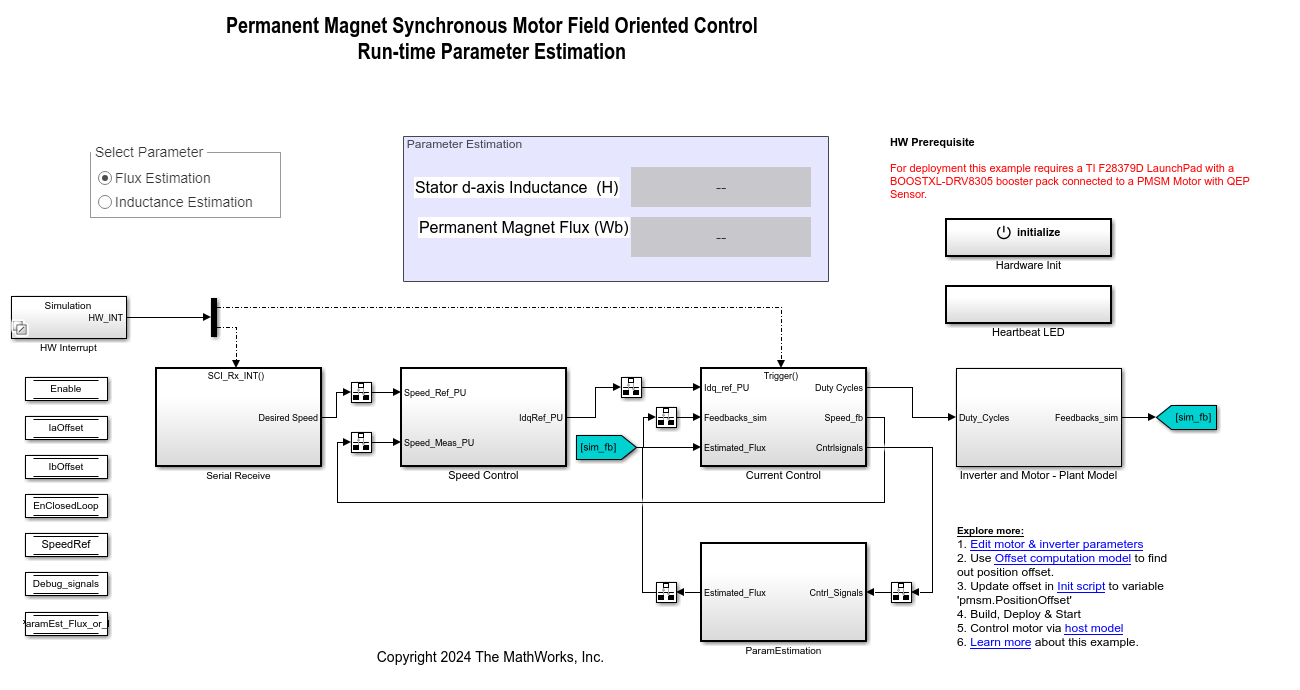

Run-Time Parameter Estimation of PMSM Using Sensor Feedback

Estimate the parameters of a permanent magnet synchronous motor (PMSM) at run-time. The example estimates the following PMSM parameters by running tests while the motor runs using a closed-loop field-oriented control (FOC) algorithm:

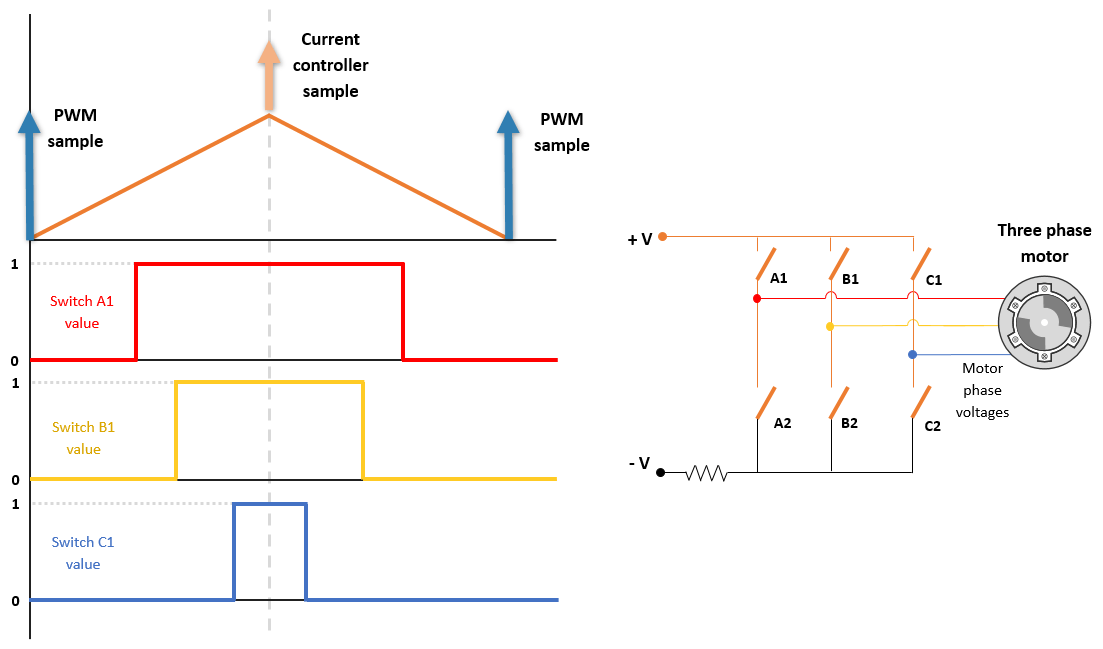

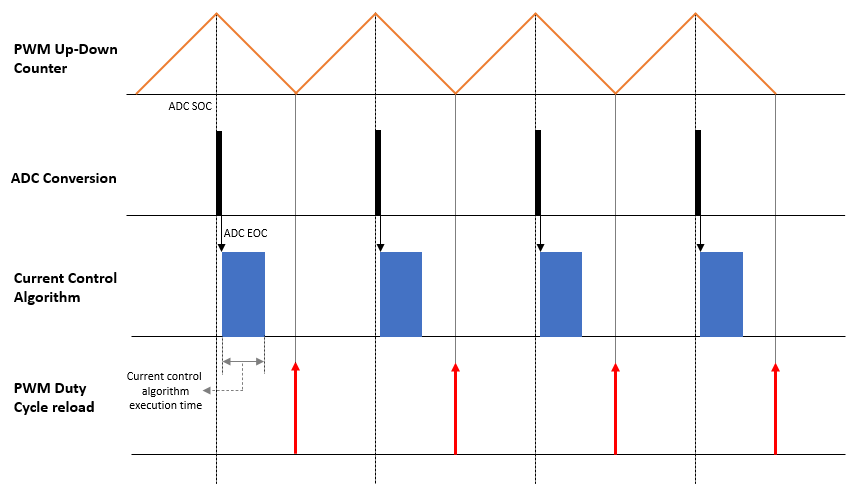

Motor Control Architectures Based on Different Current Sampling and PWM Frequencies

Enables you to implement different motor control architectures that use non-identical sampling rates for ADC conversion, PWM, and current controller algorithm to run a permanent magnet synchronous motor (PMSM) using field-oriented control (FOC).

Detect Unbalanced Motor by Using Neural Network

Detect a mechanically unbalanced spinning motor by using a neural network (NN) developed using Deep Learning Toolbox™.

MATLAB Command

You clicked a link that corresponds to this MATLAB command:

Run the command by entering it in the MATLAB Command Window. Web browsers do not support MATLAB commands.

Web サイトの選択

Web サイトを選択すると、翻訳されたコンテンツにアクセスし、地域のイベントやサービスを確認できます。現在の位置情報に基づき、次のサイトの選択を推奨します:

また、以下のリストから Web サイトを選択することもできます。

最適なサイトパフォーマンスの取得方法

中国のサイト (中国語または英語) を選択することで、最適なサイトパフォーマンスが得られます。その他の国の MathWorks のサイトは、お客様の地域からのアクセスが最適化されていません。

南北アメリカ

- América Latina (Español)

- Canada (English)

- United States (English)

ヨーロッパ

- Belgium (English)

- Denmark (English)

- Deutschland (Deutsch)

- España (Español)

- Finland (English)

- France (Français)

- Ireland (English)

- Italia (Italiano)

- Luxembourg (English)

- Netherlands (English)

- Norway (English)

- Österreich (Deutsch)

- Portugal (English)

- Sweden (English)

- Switzerland

- United Kingdom (English)