Mapped SI Engine

Spark-ignition engine model using lookup tables

Libraries:

Powertrain Blockset /

Propulsion /

Combustion Engines

Vehicle Dynamics Blockset /

Powertrain /

Propulsion

Description

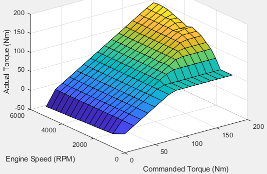

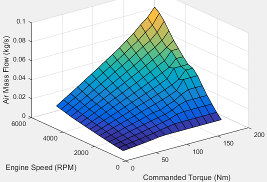

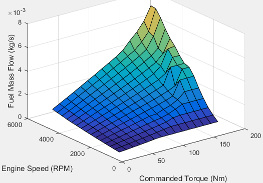

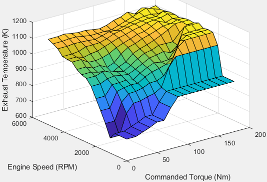

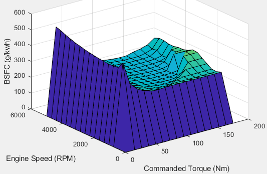

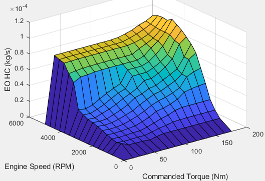

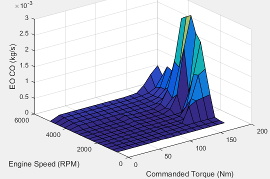

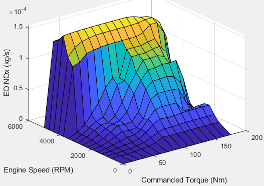

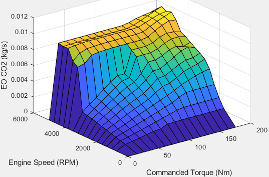

The Mapped SI Engine block implements a mapped spark-ignition (SI) engine model using power, air mass flow, fuel flow, exhaust temperature, efficiency, and emission performance lookup tables. You can use the block for:

Hardware-in-the-loop (HIL) engine control design

Vehicle-level fuel economy and performance simulations

The block enables you to specify lookup tables for these engine characteristics. The lookup tables, developed with the Model-Based Calibration Toolbox™, are functions of commanded torque, Tcmd, brake torque, Tbrake, and engine speed, N. If you select Input engine temperature, the tables are also a function of engine temperature, TempEng.

| Table | Input Engine Temperature Parameter Setting | |

|---|---|---|

off | on | |

Power | ƒ(Tcmd,N) | ƒ(Tcmd,N,TempEng) |

Air | ƒ(Tbrake,N) | ƒ(Tbrake,N,TempEng) |

Fuel | ||

Temperature | ||

Efficiency | ||

HC | ||

CO | ||

NOx | ||

CO2 | ||

PM | ||

To bound the Mapped SI Engine block output, the block does not extrapolate the lookup table data.

Virtual Calibration

If you have Model-Based Calibration Toolbox, click Calibrate Maps to virtually calibrate the 2D lookup tables using measured data. The dialog box steps through these tasks.

Task | Description | ||||

|---|---|---|---|---|---|

Import firing data | Import this loss data from a file. For example, open

For more information, see Using Data (Model-Based Calibration Toolbox).

Collect firing data at steady-state operating conditions when injectors deliver the fuel. Data should cover the engine speed and torque operating range. Model-Based Calibration Toolbox uses the firing data boundary as the maximum torque. To filter or edit the data, select Edit in Application. The Model-Based Calibration Toolbox Data Editor opens. | ||||

Import non-firing data | Import this non-firing data from a file. For example, open

Collect non-firing (motoring) data at steady-state operating conditions when fuel is cut off. All non-firing torque points must be less than zero. Non-firing data is a function of engine speed only. | ||||

Generate response models | For both firing and non-firing data, the Model-Based Calibration Toolbox uses test plans to fit data to Gaussian process models (GPMs). To assess or adjust the response model fit, select Edit in Application. The Model-Based Calibration Toolbox Model Browser opens. For more information, see Model Assessment (Model-Based Calibration Toolbox). | ||||

Generate calibration | Model-Based Calibration Toolbox calibrates the firing and non-firing response models and generates calibrated tables. To assess or adjust the calibration, select Edit in Application. The Model-Based Calibration Toolbox CAGE Browser opens. For more information, see Calibration Lookup Tables (Model-Based Calibration Toolbox). | ||||

Update block parameters | Update the block lookup table and breakpoint parameters with the calibration. |

Cylinder Air Mass

The block calculates the normalized cylinder air mass using these equations.

The equations use these variables.

| L | Normalized cylinder air mass |

Nominal engine cylinder air mass at standard temperature and pressure, piston at bottom dead center (BDC) maximum volume, in kg | |

Crankshaft revolutions per power stroke, rev/stroke | |

| Standard pressure | |

| Standard temperature | |

Ideal gas constant for air and burned gas mixture | |

Displaced volume | |

Number of engine cylinders | |

| N | Engine speed |

Engine air mass flow, in g/s |

Turbocharger Lag

To model turbocharger lag, select Include turbocharger lag effect. During throttle control, the time constant models the manifold filling and emptying dynamics. When the torque request requires a turbocharger boost, the block uses a larger time constant to represent the turbocharger lag. The block uses these equations.

|

Dynamic torque |

|

|

Boost time constant |

|

|

Final time constant |

|

The equations use these variables.

| Tbrake |

Brake torque |

| Tstdy | Steady-state target torque |

| τbst |

Boost time constant |

| τbst,rising, τbst,falling |

Boost rising and falling time constant, respectively |

| τeng |

Final time constant |

| τthr | Time constant during throttle control |

| ƒbst(N) | Boost torque speed line |

| N | Engine speed |

Fuel Flow

To calculate the fuel economy for high-fidelity models, the block uses the volumetric fuel flow.

The equation uses these variables.

| Fuel mass flow | |

| Sgfuel | Specific gravity of fuel |

| Qfuel | Volumetric fuel flow |

Power Accounting

For the power accounting, the block implements these equations.

| Bus Signal | Description | Equations | ||

|---|---|---|---|---|

|

|

| Crankshaft power | |

|

|

| Fuel input power | ||

| Power loss | |||

|

| Not used | |||

The equations use these variables.

LHV | Fuel lower heating value |

ω | Engine speed, rad/s |

| Fuel mass flow | |

τeng | Fuel mass per injection time constant |

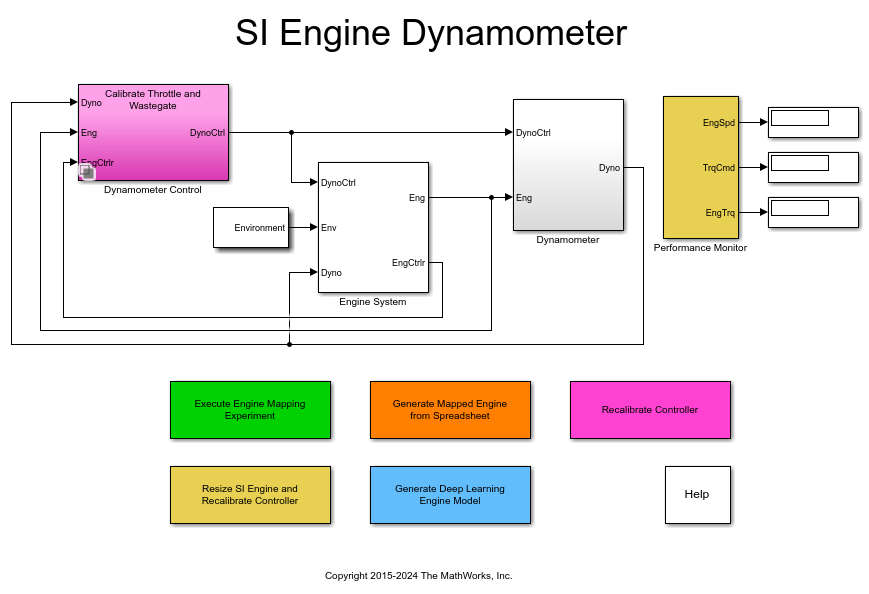

Examples

Ports

Input

Output

Parameters

Extended Capabilities

Version History

Introduced in R2017a