Battery Coolant Control

Libraries:

Simscape /

Battery /

BMS /

Thermal Management

Description

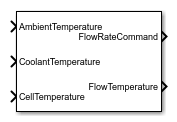

The Battery Coolant Control block implements a battery coolant control algorithm.

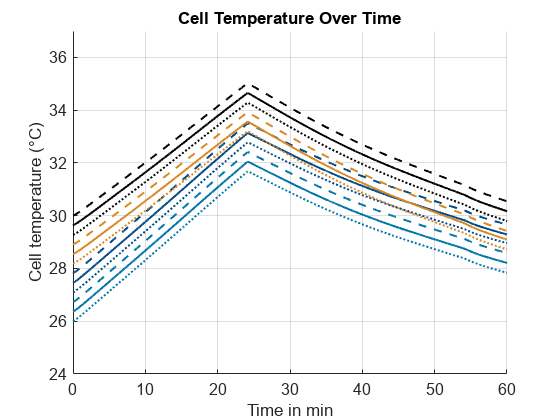

Temperature is crucial in batteries because high temperatures significantly decrease the battery life. It is import to keep the temperature of each cell of the battery under control and activate heaters or coolers to keep the temperature within safe limits. If the temperature is too high, the battery management system (BMS) enables a cooling fan.

This block supports single-precision and double-precision floating-point simulation.

Note

To enable single-precision floating-point simulation, the data type of all inputs and

parameters must be single.

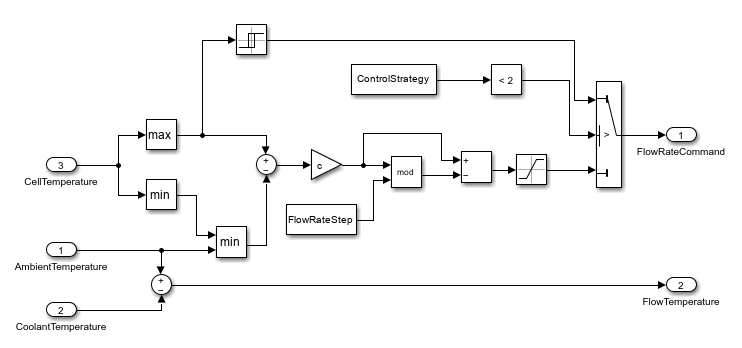

This diagram shows the structure of the block:

Equations

The Battery Coolant Control block uses this equation to compute the flow temperature:

where Tamb is the ambient temperature and Tcool is the coolant temperature.

If the value at the FlowRateCommand output port is equal to

0, there is no flow in the battery. If this value is equal to

1, then the flow rate in the battery takes its highest

possible value.

If you set the Control strategy parameter to

ON-OFF control, the block uses this equation to

calculate the flow rate command:

where

Thottest is the temperature of the hottest cell.

Ton is the switch-on temperature.

Toff is the switch-off temperature, which must be less than Ton.

FlowRateCommandold is the flow rate command at the previous time step.

If you set the Control strategy parameter to Step

control, the block uses these equations to calculate the flow rate command:

where

Tcoolest is the temperature of the coolest cell.

step is the flow rate step command. For example, if step = 0.2, the value at the FlowRateCommand output port is one of these values: [0,0.2,0.4,0.6,0.8,1].

c controls how aggressive the coolant strategy is. This value is a constant such that, if f(ΔT)≥ 1, the value at the FlowRateCommand output port is equal to 1. Otherwise, the block scales the flow rate command linearly to

0.

The step control strategy allows intermediate flow commands with the value you specify for the Flow rate step parameter. To compute the actual command, the block uses a function of the temperature gradient.