Aircraft Fuel Supply System with Three Tanks

Warning: This example uses the hydraulic domain, which will be removed in a future release. Find an equivalent example model that uses the isothermal liquid domain here: Aircraft Fuel Supply System with Three Tanks. To convert models to the isothermal liquid domain, use the hydraulicToIsothermalLiquid tool.

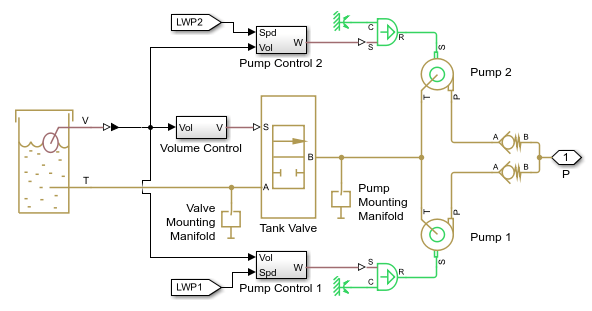

The fuel supply system represented in the example consists of three tanks and an engine. The engine is fed from the central tank, while fuel from the left wing tank and the right wing tank is pumped to the central tank with respective pumping stations. Each pumping station consists of two centrifugal pumps, connected in parallel, with check valves installed in the pump outlets to prevent back flow. The pumps are driven by prime movers at angular velocity of 7200 rpm. The movers are simulated with the ideal angular velocity source.

The central tank bottom is elevated by 36 in with respect to the reference plane, which is drawn horizontally through the entry point of the engine. The side tank bottoms are elevated by 4.2 in each.

The left wing and the right wing tanks are equipped with the volume control block intended to cut the outlet off if fluid volume in the tank becomes less than preset volume. A similar block in the central tank controls both the tank overfill and the exposure of its highest port. In all tanks, the cutoff is performed with the 2-way valves.

Model

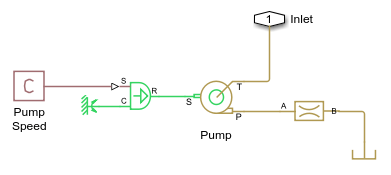

Engine Subsystem

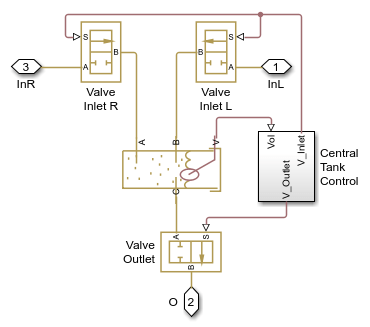

Tank System Center Subsystem

Tank System Left Wing Subsystem

Simulation Results from Simscape Logging

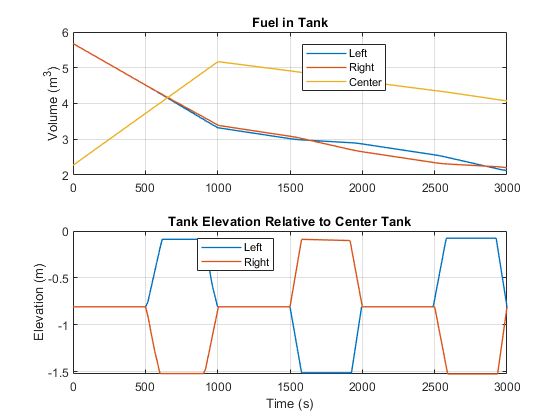

The plots below show the amount of fuel remaining in the tanks. The rate of fuel consumption from each tank is affected the pressure drop across the fuel lines due to the elevation change relative to the center tank.

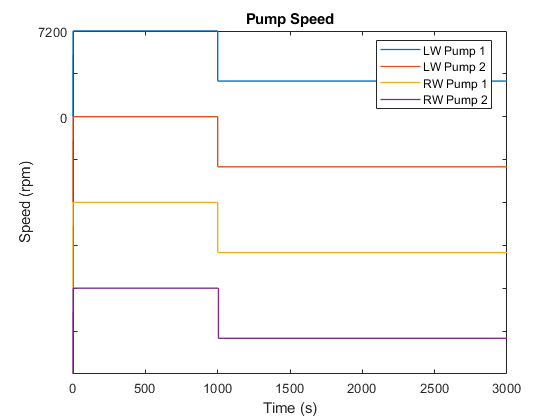

The plots below show the speed for all four pumps in the fuel supply system. For some test sequences, pump speeds drop below the maximum speed to observe the effect on the fuel levels in the tanks.

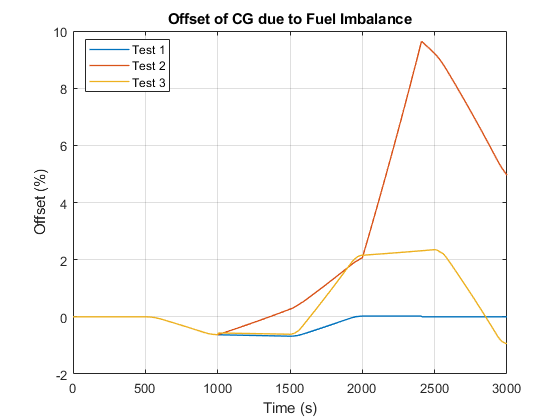

The plot below shows the offset of the CG from the fuel on the aircraft as a percentage of the half the distance between the left and right fuel tanks. The plots show the results for three tests where different combinations of pump failures are triggered.