Positive-Displacement Compressor (G)

Libraries:

Simscape /

Fluids /

Gas /

Turbomachinery

Description

The Positive-Displacement Compressor (G) block represents a positive-displacement compressor, such as a reciprocating piston, rotary screw, rotary vane, or scroll, in a gas network. Port R and port C are mechanical rotational conserving ports associated with the compressor shaft and casing, respectively. When there is positive rotation at port R with respect to port C, gas flows from port A to port B. The block may not be accurate for reversed flow.

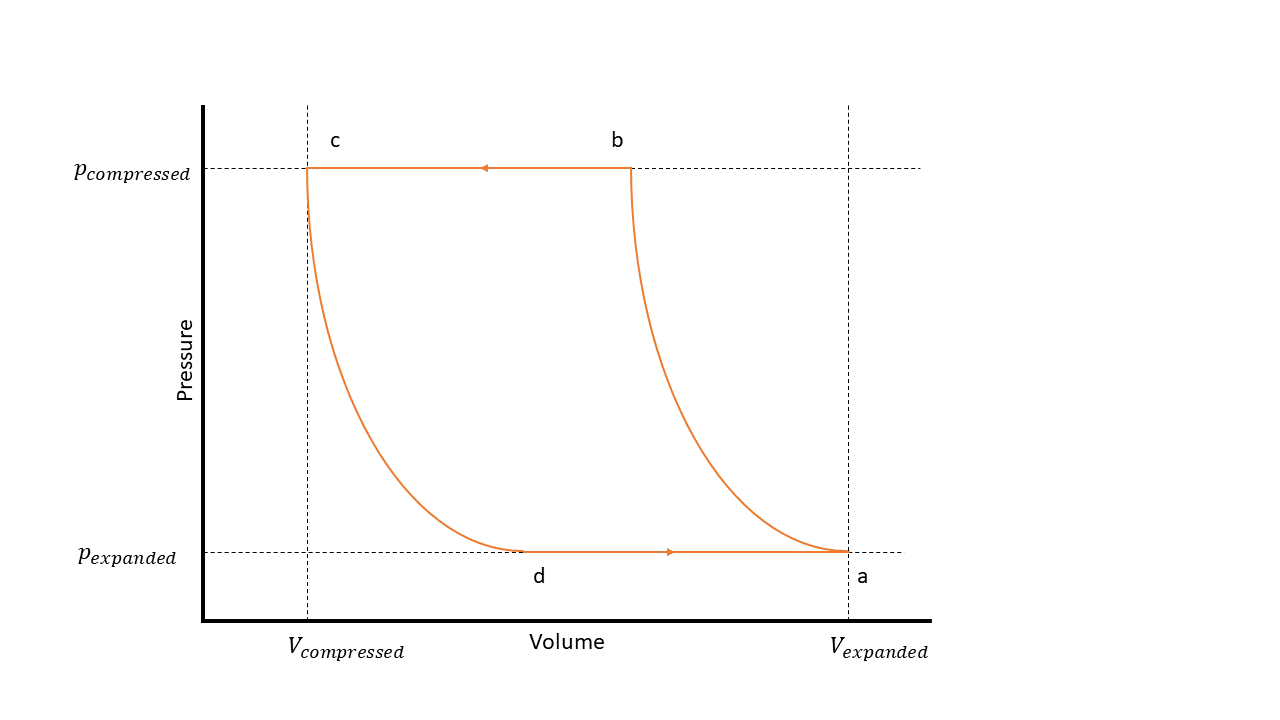

The figure shows the steps of a piston compressor on a P-V diagram, which has these states:

a — The compressor cylinder is full at inlet pressure.

b — The pressure inside the compressor exceeds that of the outlet, which results in fluid discharge.

c — The compressor reaches the top of the piston stroke, and only the clearance volume remains in the cylinder.

d — The pressure inside the cylinder drops below the inlet pressure, which results in fluid intake.

Mass Flow Rate

The block calculates the mass flow rate as

where:

ṁ is the mass flow rate.

ω is the angular velocity of port R relative to port C.

vs is the specific volume at the inlet. The block calculates this value from the nominal inlet conditions.

Vdisp is the displacement volume that the block uses.

Displacement Volume

When you set Displacement specification to

Volumetric displacement, the block uses the

Displacement volume parameter as the value for

Vdisp.

When you set Displacement specification to

Nominal mass flow rate and shaft speed, the block

calculates the displacement volume as

where:

ṁnominal is the value of the Nominal mass flow rate parameter.

ωnominal is the value of the Nominal shaft speed parameter.

ηVnominal is the value of the Nominal volumetric efficiency parameter when the Efficiency specification parameter is

Analytical. When the Volumetric efficiency parameter isTabulated, the block uses thetablelookupfunction to interpolate ηVnominal as a function of the shaft speed and the pressure ratio.

Volumetric Efficiency

You can parameterize the volumetric efficiency by using analytical values or a lookup table.

When you set Efficiency specification to

Analytical, the block calculates the volumetric

efficiency by using analytical values. When the Thermodynamic

model parameter is Polytropic, the

volumetric efficiency is

where pin and pout are the inlet and outlet pressures, respectively, and n is the value of the Polytropic exponent parameter. The block calculates the clearance volume fraction, C, as

where ηVnominal is the value of the Nominal volumetric efficiency parameter and pratio is the value of the Nominal pressure ratio parameter.

When the Thermodynamic model parameter is

Isentropic, the volumetric efficiency is

where vin and vout are the inlet and outlet specific volumes, respectively. The block calculates the clearance volume fraction, C, as

where is the nominal specific volume ratio. The block calculates this value from the nominal inlet conditions and the isentropic efficiency.

When you set Efficiency specification to

Tabulated, the block calculates the volumetric

efficiency by interpolating the values of the Volumetric efficiency

table, eta_vol(pr,w) parameter as a function of the shaft speed

and the pressure ratio.

Continuity Equations

The block conserves mass such that

where ṁA and ṁB are the mass flow rates at ports A and B, respectively. The block conserves energy such that

where Δht is the change in specific total enthalpy and ṁAΔht is the fluid power, which is equal to the mechanical power, torque*ω.

When the Thermodynamic model parameter is

Polytropic, the fluid power is

where the block uses the polytropic relationship to relate pin, pout, vin, and vout.

When the Thermodynamic model parameter is

Isentropic, the fluid power is

The block calculates

Δht from the isentropic efficiency,

ηisen. When the

Efficiency specification parameter is

Analytical,

ηisen is equal to the value of the

Isentropic efficiency parameter. When the

Efficiency specification parameter is

Tabulated, the block calculates

ηisen by interpolating the values

of the Isentropic efficiency table, eta_isen(pr,w) parameter as

a function of the pressure ratio and the shaft speed.

Visualizing the Volumetric Efficiency

To visualize the block volumetric efficiency, right-click the block and select Fluids > Plot Volumetric Efficiency.

Each time you modify the block settings, click Reload Data in the figure window.

When you set Efficiency specification to

Analytical and Thermodynamic

model to Polytropic, the block plots the

compressor volumetric efficiency against the pressure ratio.

When you set Efficiency specification to

Analytical and Thermodynamic

model to Isentropic, the block plots the

compressor volumetric efficiency against the pressure ratio at

Tout nom, the calculated nominal

outlet temperature.

When you set Efficiency specification to

Tabulated, the block plots the compressor volumetric

efficiency against the pressure ratio for each element in the Shaft speed

vector, w parameter.

Assumptions and Limitations

The block may not be accurate for flow from port B to port A.

The block assumes that the flow is quasi-steady. The compressor does not accumulate mass.

Examples

Ports

Conserving

Parameters

References

[1] Mitchell, John W., and James E. Braun. Principles of Heating, Ventilation, and Air Conditioning in Buildings. Hoboken, NJ: Wiley, 2013.