Pilot Valve Actuator (IL)

Single-acting or double-acting actuator controlled by a pilot pressure in an isothermal liquid network

Libraries:

Simscape /

Fluids /

Isothermal Liquid /

Valves & Orifices /

Valve Actuators & Forces

Description

The Pilot Valve Actuator (IL) block models a single-acting or double-acting actuator controlled by a pilot pressure for control of a connected valve or orifice in an isothermal liquid network.

For the single-acting actuator, when the control pressure, PX – Patm, exceeds the Spring preload force at port X, the piston begins to actuate in the direction assigned by the Mechanical orientation parameter.

For the double-acting actuator, the control pressure Pcontrol is the difference between PX – Patm and PY – Patm. The piston actuates in the direction of the larger applied pressure differential, opposing the spring force at the opposite port. When the piston motion reverses, this spring does not extend and does not exert a counterbalancing force on the piston position.

The pistons at port X and port Y are attached to a single spool. Both springs restore the spool to its neutral position when Fspool falls below the opposing spring preload force. For single-acting actuators, the neutral position is at port X. For double-acting actuators, the neutral position is at the center of the actuator.

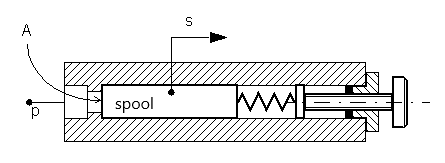

Single-Acting Actuator

The force on the piston is created by the pressure differential between port X and atmospheric pressure:

where AX is the Piston area at port X. When Fspool is greater than the Spring preload force at port X, the piston begins to move.

Schematic of a Single-Acting Actuator

The instantaneous piston displacement is calculated as:

where the steady piston position, xsteady, is the piston position at the current pressure differential, proportional to the spring force at maximum piston stroke:

where:

Fpre is the Spring preload force at port X.

Fmax is the maximum spring force acting against piston displacement, and where K is the Spring stiffness at port X.

xstroke is the Piston stroke from port X.

ε is the Mechanical orientation, which indicates piston movement in a positive direction (extension) or negative direction (retraction).

If the force on the piston is less than the Spring preload force at X, the piston remains at the neutral position or moves to the neutral position. If the force on the piston meets or exceeds the maximum spring force, the piston remains at the stroke until the applied pressure changes.

Double-Acting Actuator

The difference between the forces at ports X and Y dictates the piston motion:

The pressure applied at port X shifts the spool away from the chamber at X and opposes the spring at port Y. Similarly, the pressure applied at port Y shifts the spool away from the chamber at Y and opposes the spring at port X. When the spool reverses direction, the formerly extended spring compresses, exerting a force on the spool. The formerly compressed spring, the spring at the port in the direction of motion, does not extend and does not influence the spool position.

Schematic of a Double-Acting Actuator

The piston displacement is calculated as:

where the steady piston position, xsteady, is the piston position at the current pressure differential, proportional to the spring force at maximum piston stroke:

where:

Fpre,X and Fpre,Y are the Spring preload force at port X and Spring preload force at port Y, respectively.

Fmax,X and Fmax,Y are the maximum spring forces acting against piston displacement at ports X and Y, respectively, where:

K is the spring stiffness per port.

xstroke is the piston stroke per port.

ε is the Mechanical orientation, which assigns the signal for piston movement as positive (extension) or negative (retraction).

If the force on the piston is less than the respective port spring preload force, the piston remains or returns to the neutral position. If the force on the piston meets or exceeds the maximum spring force for the respective port, the piston remains at the piston stroke until the applied pressure changes.

Numerically-Smoothed Force

When the actuator is close to full extension or full retraction, you can maintain numerical robustness in your simulation by adjusting the block Smoothing factor. With a nonzero smoothing factor, a smoothing function is applied to all calculated forces, but primarily influences the simulation at the extremes of the piston motion.

When Actuator configuration is set to

Single-acting, the normalized force on the piston is

calculated as:

When Actuator configuration is set to

Double-acting, the normalized force on the piston at

X is calculated as:

and the normalized force at Y is calculated as:

When the Smoothing factor is nonzero, the block smoothes each

normalized force between 0 and 1.

For more information, see Numerical Smoothing.

Examples

Ports

Conserving

Output

Parameters

Extended Capabilities

Version History

Introduced in R2020a