Simscape Multibody (旧 SimMechanics) は、ロボット、車両サスペンション、建設機械、航空機の着陸装置などの 3D 機械システムにマルチボディ シミュレーション環境を提供します。ボディ、ジョイント、拘束、力要素、およびセンサーを表すブロックを使用して、マルチボディシステムをモデル化することができます。Simscape Multibody は、完全な機械システムの運動方程式を定式化し、求解します。すべての質量、慣性、ジョイント、拘束、および 3D ジオメトリを含む完全な CAD アセンブリをモデルにインポートすることができます。自動生成された 3D アニメーションにより、システムダイナミクスを可視化することができます。

Simscape Multibody は、制御システムの開発とシステムレベルでのパフォーマンスのテストを支援します。MATLAB 変数および式を使用してモデルをパラメーター化し、Simulink でマルチボディシステムの制御システムを設計することができます。Simscape 製品ファミリのコンポーネントを使用して、油圧、電気、空気圧、およびその他の物理システムをモデルに統合することができます。ハードウェアインザループ (HIL) システムを含むその他のシミュレーション環境へモデルを展開するため、Simscape Multibody では C コード生成をサポートしています。

3D メカニズムのシミュレーション

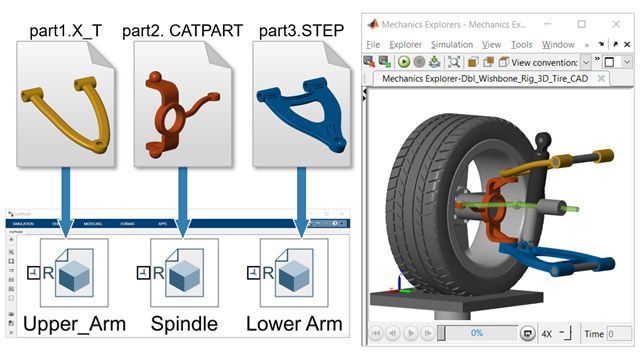

3D メカニズムのマルチボディモデルを作成します。パラメーター化された 3D ジオメトリまたは CAD データを使用してパーツを定義します。パーツをジョイントで接続して、自由度を定義します。

CAD インポート

CAD 設計を自動的に変換して、システムのデジタルツインを作成します。CATIA®、Creo™、Inventor®、NX™、Solid Edge®、SolidWorks®、Parasolid®から直接ファイルを参照します。

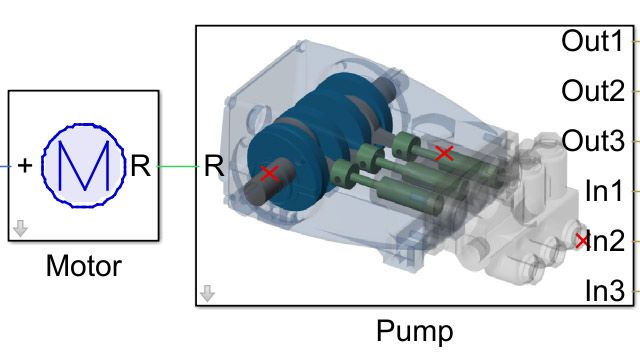

電気および油圧による作動

電子、油圧、空気圧、およびその他のシステムを 3D 機械モデルに直接接続します。アクチュエータ技術を評価して、性能要件を満たしているかどうかを確認します。

接触力

CAD ソフトウェアで定義されたパラメトリックとソリッドの間の断続的および永続的な接触をモデル化します。カスタムフォース法を定義します。車両と道路の接触にタイヤモデルを使用します。

可とう体

理論的および有限要素モデリング手法を使用して可とう体をモデル化します。MATLAB を使用してプロパティを変更し、伸張、たわみ、ねじりがシステムに与える影響を確認します。

パラメトリック設計

MATLAB を使用して、長さ、質量、電圧などの設計パラメーターを変更します。抽象モデルで動的シミュレーションを使用して、少ない反復で機械設計を完成させます。

モデルの展開

Simscape モデルを C コードに変換して、制御アルゴリズムをテストします。物理テストを実行する前に、dSPACE®、Speedgoat、OPAL-RT、その他のリアルタイムシステムで HIL テストを実行します。

MATLAB と Simulink

MATLAB を使用して、モデルアセンブリ、テスト、後処理などのタスクを自動化します。Simulink を使用して、制御アルゴリズムとハードウェア設計を単一環境に統合します。

調査から運用まで

Simscape モデルは、デジタルツインとして、要件の調整、制御システムの設計、組み込みコントローラーのテスト、および稼働中の設備のサポートに役立ちます。

製品リソース:

Simscape 製品ファミリ

Simscape 製品ファミリには、物理システムをシミュレーションするためのモデルとソルバー技術が用意されています。コンポーネントを回路図に組み込むことで、電気、機械、流体、その他の物理システムをモデル化します。

Simscape

マルチドメイン物理システムのモデル化およびシミュレーション

Simscape Electrical

電子、メカトロニクス、および電力システムのモデル化とシミュレーション

Simscape Battery

バッテリーおよびエネルギー貯蔵システムの設計とシミュレーション

Simscape Fluids

流体システムのモデル化とシミュレーション

Simscape Driveline

回転機械システムと並進機械システムのモデル化およびシミュレーション

Simscape Multibody

マルチボディ機械システムのモデル化およびシミュレーション

「Simulink、Simscape Multibody、および Simulink Coder により、MRO 車両の正確な CAD モデルから、リアルタイムで実行される C コードに自律的に移行できるようになりました。」

Jim Chapel, Lockheed Martin Space Systems

あなたは学生ですか?

ご所属の学校にはすでに Campus-Wide License が導入されていて、MATLAB、Simulink、その他のアドオン製品を利用できる可能性があります。