Synchronizer

Mechanical synchronizer

Libraries:

Simscape /

Driveline /

Clutches

Description

The Synchronizer block represents a synchronizer that contains a dog clutch, a cone clutch, and a translational detent. Synchronizers facilitate smooth shifting in manual transmissions by equalizing the speeds of gears before engagement, reducing gear clash and ensuring seamless transitions between different gear ratios.

The shift linkage first translates to engage the cone clutch. Frictional torque causes the shift linkage and cone clutch shaft to rotate at equal speed. When the force acting on the shift linkage exceeds the detent force, the dog clutch can engage.

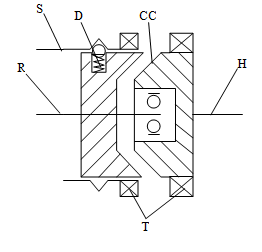

The schematic illustrates a synchronizer in the disengaged state. In this state, the ring (R) and hub (H) shafts can spin independently at different speeds. To synchronize ring and hub shaft speeds, the shift linkage (S) translates toward the hub shaft to engage the cone clutch. The friction surfaces of the cone clutch produce a frictional torque that equalizes the rotational speeds of the ring and hub shafts. The dog clutch teeth (T) can engage when the translational force acting on the shift linkage exceeds the peak detent force. The peak detent force should allow sufficient time and normal force to equalize ring and hub shaft speeds so that the dog clutch can engage.

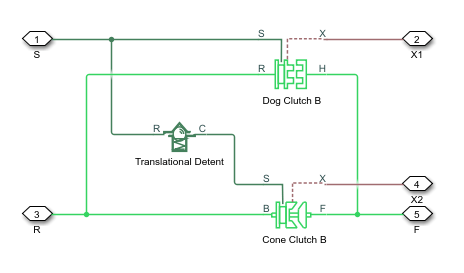

The model implements the Dog Clutch, Cone Clutch, and Translational Detent blocks. Refer to each block reference page for more information on the corresponding block function. You can use a similar approach to model customized versions of the synchronizer. One example is the Transmission (Detailed) subsystem in the Vehicle with Manual Transmission example model.

Connections R and H are mechanical rotational conserving ports that represent the ring (R) and hub (H), respectively. Connection S is a mechanical translational conserving port that represents the ring shifter handle.

Connections X1 and X2 are physical signal outputs that report the shift linkage positions of the dog clutch and cone clutch, respectively. The shift linkage positions are zero when the clutch is fully disengaged. When the dog clutch is fully engaged, the dog clutch shift linkage position has a magnitude equal to the sum of the dog clutch ring-hub gap and the tooth height. When cone clutch is fully engaged, the cone clutch shift linkage position has a magnitude equal to the cone clutch ring-hub gap.

Dog Clutch Torque Transmission Models

You can choose from these torque transmission models.

When you set Torque transmission model to

Friction clutch approximation - Suitable for HIL

and, the block treats the clutch engagement as a friction

phenomenon between the ring and the hub. This setting is better suited for

linearization, fixed-step simulation, and hardware-in-loop (HIL) simulation. The

block uses a composite implementation of the Fundamental Friction Clutch

block.

When you use this setting, the clutch has three possible configurations: disengaged, engaged, and locked. When disengaged, the contact force between the ring and the hub is zero. This force remains zero until the shift linkage reaches the minimum position for engagement.

When the ring-hub tooth overlap, h, exceeds the minimum value for engagement, the contact force between the two components begins to increase linearly with the shift linkage position, z.

At full engagement, the contact force reaches its maximum value and the clutch state switches to locked. In this state, the ring and the hub spin as a unit without slip. To unlock the clutch, the transmitted torque must exceed the value of the Maximum transmitted torque parameter.

When you set Torque transmission model to

Dynamic with backlash, the block simulates clutch

phenomena such as backlash, torsional compliance, and contact forces between

ring and hub teeth. This model provides greater accuracy than the friction

clutch approximation.

When you use this setting, the clutch has two possible configurations: disengaged and engaged. When disengaged, the contact force between the ring and the hub is zero. This force remains zero until the shift linkage reaches the minimum position for engagement.

When the ring-hub tooth overlap, h, exceeds the engagement threshold value, the clutch transmits torque. This torque is the sum of torsional spring and damper components, including backlash between the ring and hub teeth, such thatwhere:

kRH is the torsional stiffness of the ring-hub coupling.

ϕ is the relative angle, about the common rotation axis, between the ring and the hub.

δ is the backlash between ring and hub teeth.

ω is the relative angular velocity between the ring and the hub. This variable describes how fast the two components slip past each other.

Compliant end stops limit the translational motion of the clutch shift linkage and the ring. The compliance model treats the end stops as linear spring-damper sets. The location of the end stops depends on the relative angle and angular velocity between the ring and hub teeth:

If the teeth align and the relative angular velocity is smaller than the maximum value for clutch engagement, the end stop location is the sum of the ring-hub clearance when fully disengaged and the tooth height. The clutch can engage in this end stop position.

If the teeth do not align or the relative angular velocity exceeds the maximum value for clutch engagement, the end-stop location is set to prevent the ring from engaging the hub. The clutch does not engage in this end stop position.

Translational friction opposes shift linkage and ring motion. This friction is the sum of Coulomb and viscous components, such thatwhere:

FZ is the net translational friction force acting on the shift linkage and ring.

kK is the kinetic friction coefficient between ring and hub teeth.

FN is the normal force between ring and hub teeth, where FN = TC/Rm.

v is the translational velocity of the shift linkage and the ring.

vth is the translational velocity threshold. Below this threshold, a hyperbolic tangent function smooths the Coulomb friction force to zero as the shift linkage and ring velocity tends to zero.

μT is the viscous damping coefficient acting on the shift linkage and the ring.

When you set Torque transmission model to

Dynamic modal, the block determines the discrete

clutch modal behavior by taking the shift linkage position from the mechanical

translational conserving port S. This setting captures more complex

clutch dynamics than the Two-mode parameterization

and is faster than the Friction clutch approximation

and Dynamic with backlash settings.

You can use the Dynamic modal setting to simulate

engagement blocking when the speed difference is too large for the clutch plates

to engage. The block represents engagement blocking as a spring-damper system

where you can parameterize the spring and damping coefficients. The engagement

modes overlap, which prevents the mode from changing until the shift linkage

position is beyond the engagement overlap region. You define the engagement

overlap region using the Tooth overlap to engage parameter.

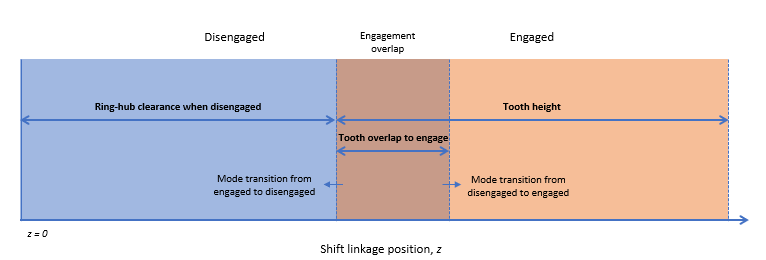

The linkage position constrains are:

z is the shift linkage position at port S.

h is the Tooth height parameter.

zGap is the Ring hub clearance when disengaged parameter.

zOverlap is the Tooth overlap to engage parameter.

ωthr is the Engagement speed threshold parameter.

The engagement mode positions are:

z = 0 — The clutch is fully disengaged.

0 < z < zGap — The clutch is disengaged when the shift linkage position is in the region defined by zGap. The clutch can transition from disengaged to engaged at x = zGap + zOverlap.

zGap < z < h — The clutch is engaged when z is in the region defined by h. The clutch can transition from engaged to disengaged when z = zGap.

z = zGap + h — The clutch is fully engaged.

z = zGap + zOverlap — When z is in the engagement overlap region, the clutch engages only when the speed difference is less than the value of the ωthr parameter.

Thermal Modeling

You can model the effects of heat flow and temperature change through an optional thermal conserving port. By default, the thermal port is hidden. To expose the thermal port, in the Clutch settings, select a temperature-dependent setting tor the Friction model parameter. Specify the associated thermal parameters for the component.

Assumptions and Limitations

The model does not account for inertia effects. You can add a Simscape™ Inertia block at each port to add inertia to the synchronizer model.